Underwater Concrete

Underwater concrete is a type of high-performance concrete used in the past, present and further. This is a special type of concrete used for special purposes.

Underwater concrete is used to construct bridge piers, harbors, sea and river defenses, development of offshore oil fields, foundations in soil with high water levels. Off-and-on shore structures can be built with this type of concrete. The use of these types of concrete avoids isolating the water. It reduces the cost of construction and there are minimal interruptions. In addition, construction could be able to do the construction quickly.

Underwater concrete is a type of high-performance concrete. It performs well in key performance indicators such as strength, workability and service lift.

Special Attention Required in Underwater Construction

- Specially designed to enhance the constructability performance in underwater construction.

- It required careful monitoring

- Selecting the right materials, use of specialized apparatus for quality control and paying special attention to the construction methodology are very important.

- Sufficient attention on mixed design

- Stability depends on the rheological properties and placement conditions

Key Features of Underwater Concrete

- Cement content is in the range of 380-600 kg/m3

- Water cement ratio in the range of 0.34 – 0.46

- Sand / Aggregate ratio 0.42 -0.5

- With a low water-cement ratio, cement content increases. as a result, underwater concrete is generally high-strength concrete.

- Generally, these types of concrete are rapid setting

- When the superplasticizers are used, it increases the high fluidity and reduction in the water-cement ratio.

- Anti-washout admixtures could be used to enhance the yield value and viscosity of the mix. Hence, improve the washout resistance and segregation resistance

- Highly flowable concrete that spread its own weight.

- Archives good compaction without vibration.

- Less segregation and bleeding of concrete.

Underwater Concrete – Concreting Methods

Underwater concreting is challenging work as it is down in somewhere which is not observable. If we can see by our naked eye, anything can be done if something goes wrong. Therefore, as discussed above, special attention shall be made when concreting of this nature is done.

Let’s discuss each concreting method in detail.

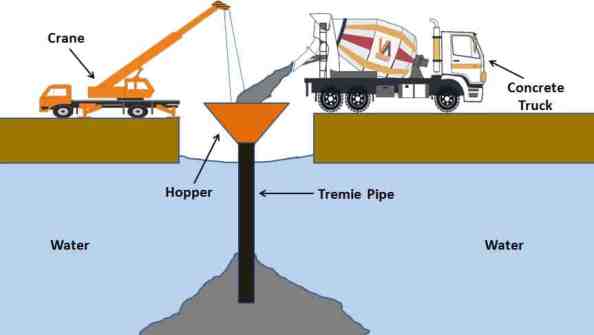

Tremie Method

This method is more common in the construction underwater construction. Most frequently, this method is applied in pile foundation construction. In addition, another construction method such as pier foundation construction also this concreting work are done using this method.

There few important factors to be considered in concrete pouring in the tremie method.

- Tremie shall be placed at the bottom and it should be touching the bottom surface.

- When the concrete is poured into the hopper, initially, it shall be sealed and shall not allow concrete to move into the pipe.

- Once the concrete is filled into the hopper, the seal shall be opened and concrete will move through the pipe.

- Then pipe shall be moved up slightly allowing concrete to flow. Once the concrete moves and is stable fill the tremie.

- Then the tremie moves slightly up. However, tremie shall not move beyond the top surface of the concrete. Tremie shall be kept within the concrete always till the concreting is completed.

- Then the top concrete surface which is in contact with the water will remain the same.

Pumping Technique

Concrete can be directly pumped in to the location.

Not like the tremie method, it required much skill and labor to handle the work. It is used in underwater concreting where the other conventional method is not applicable.

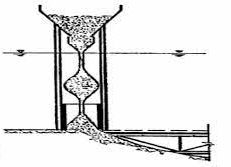

Hydro Valve Method

This method is using pipe do the concreting. It is somewhat similar to the tremie method.

However, there is a difference. The weight of the concrete balance the movement of the concrete. When concrete is poured it moves under gravity.

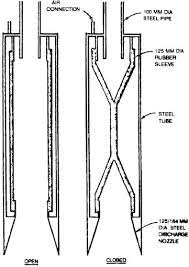

Pneumatic Value Method – Underwater Concrete

Pneumatic valves connected at the end of the pipe control the movement of the concrete. They can operate from outside to control the movement of the concrete.

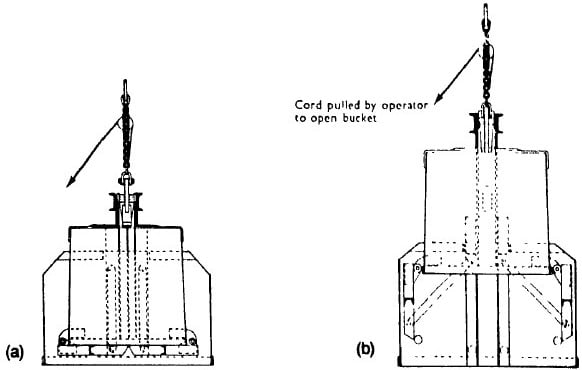

Skip Method of Underwater Concrete

This method prevents concrete washing and concrete can be brought into the required position.

The following figure indicates the skip method and open-close position of the bucket.

In addition, there are other methods used for underwater concrete.

- Tilting Pallet Barge Method

- Preplaced Aggregate Concrete

- Toggle Bags Methods

- Bagged Concrete Method