Air Entraining Concrete | a Special Concrete

Air entrainment is a fundamental physical process in civil engineering that is integral to designing and building structures that are both physically resilient and cost-effective. When it comes to concrete, air entraining concrete is a great solution to cconsiderdue to its superior strength and durability. As civil engineers, it is important to understand the implications of air entrainment in concrete and how it affects the overall quality and performance of a structure. This blog article will discuss the basics of air entrainment and explore the practical applications of this process in civil engineering projects.

What is Air Entraining Concrete

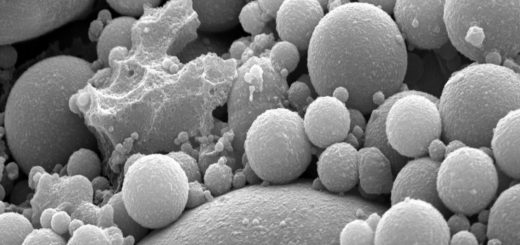

Air entrainment is the process of adding small air bubbles to concrete. This is typically done by adding an air-entraining agent to the concrete mix. The air bubbles serve as tiny pockets of air that help to increase the overall porosity of the concrete. This increased porosity makes the concrete more resistant to freeze-thaw cycles and helps to prevent the formation of cracks and other surface defects.

Where it Used and Its Benefits

Air entrainment is a common practice in the construction of bridges and other structures that are exposed to severe weather conditions. The added air bubbles help to protect the concrete from the damaging effects of freezing and thawing. In addition, air entrainment can also be used to improve the workability of concrete. The added air bubbles help to increase the flowability of the concrete, making it easier to place and finish.

While air entrainment is a beneficial process, it is important to note that too much air can negatively impact the strength and durability of concrete. As such, it is important to carefully control the air content of the concrete mix. The air content of the concrete should be monitored throughout the mixing process and adjusted as needed to achieve the desired results.

In conclusion, air entrainment is a useful process that can be used to improve the strength and durability of concrete. When used properly, air entrainment can help to create a concrete mix that is better able to withstand the rigors of freeze-thaw cycles and other harsh weather conditions.

Advantages of Air Entraining Concrete

- Improve the workability of concrete

- Control the effect of freezing and thawing

- Could have good sulfate resistance.

- Low bleeding of concrete

- Low segregation of concrete

- Reduce the cracks form due to the shrinkage of concrete

Disadvantages

- Reduction in the compressive strength of concrete can be expected.

- Increase in the porosity of concrete where it is not useful in some applications

- Low density of concrete

- this concrete need to be produced with much care and with careful monitoring