Tensile Strength of Rebar

The tensile strength of rebar and the compressive strength of concrete are the two main strength parameters we consider in structural designs.

We use rebar where the concrete is subjecting to tensile stresses and when it does not strong enough to act along to carry the loads.

Thus, the reinforcement steel is provided for the structural element to act together with concrete. Steel weak in compression when act along. The composite action is the best way for this issue.

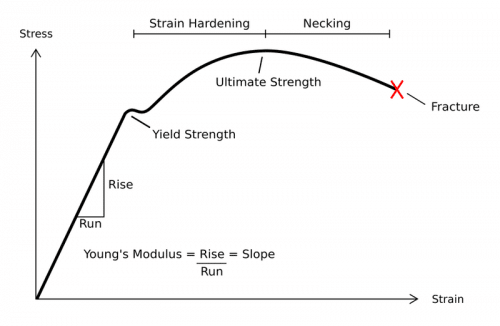

Let’s a typical variation of the stress-strain of the reinforcement bars.

What is the Tensile Strength of Rebar?

The above figure indicates the typical variation of the stress and strain cure of steel.

Initially, it’s straight and after some point (we called yielding) it becomes nonlinear.

The maximum stress (ultimate stress) the reinforcement bar subjected when elongating is called the tensile strength of rebar.

This the peak and after that necking starts and then stress reduces as shown in the above figure. The tensile strength of rebar is a very important factor that we need to know in nonlinear designs.

In linear design, the strength of the reinforcement is basically considered up to the yielding. However, when we concentrated on the nonlinear designs, we used most out of the stress that rebar can be bared without failure.

Earthquake designs, desing structures for blast loading, accidental loads designs, etc mostly occupy the nonlinear range of the reinforcement steel.

Variation of Tensile Strength of Rebar

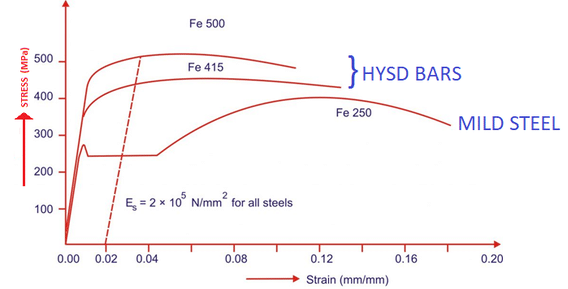

There are deviations in the tensile strength or the ultimate strength of the reinforcement bars.

When the strength of the rebar increases, its elongation reduces. Thus, it takes less elongation (or strain) to reach the ultimate tensile stress.

As indicated in the above figure, tensile strength increases with the increase of the reinforcement steel class. However, it shows less strain to reach the failure.

How to Test Tensile Strenght of Rebar

Firstly, it is required to select the samples for testing. Sampling is done as per the relevant code of practices or project specifications.

According to BS 4449:2005, three test pieces for each nominal diameter for every 30 tons shall be tested.

There are different testing machines developed to carry out tensile strength testing. The following figure indicates a typical testing machine.

As indicated in the above figure, the sample is positioned and then the force will be applied until it failed.

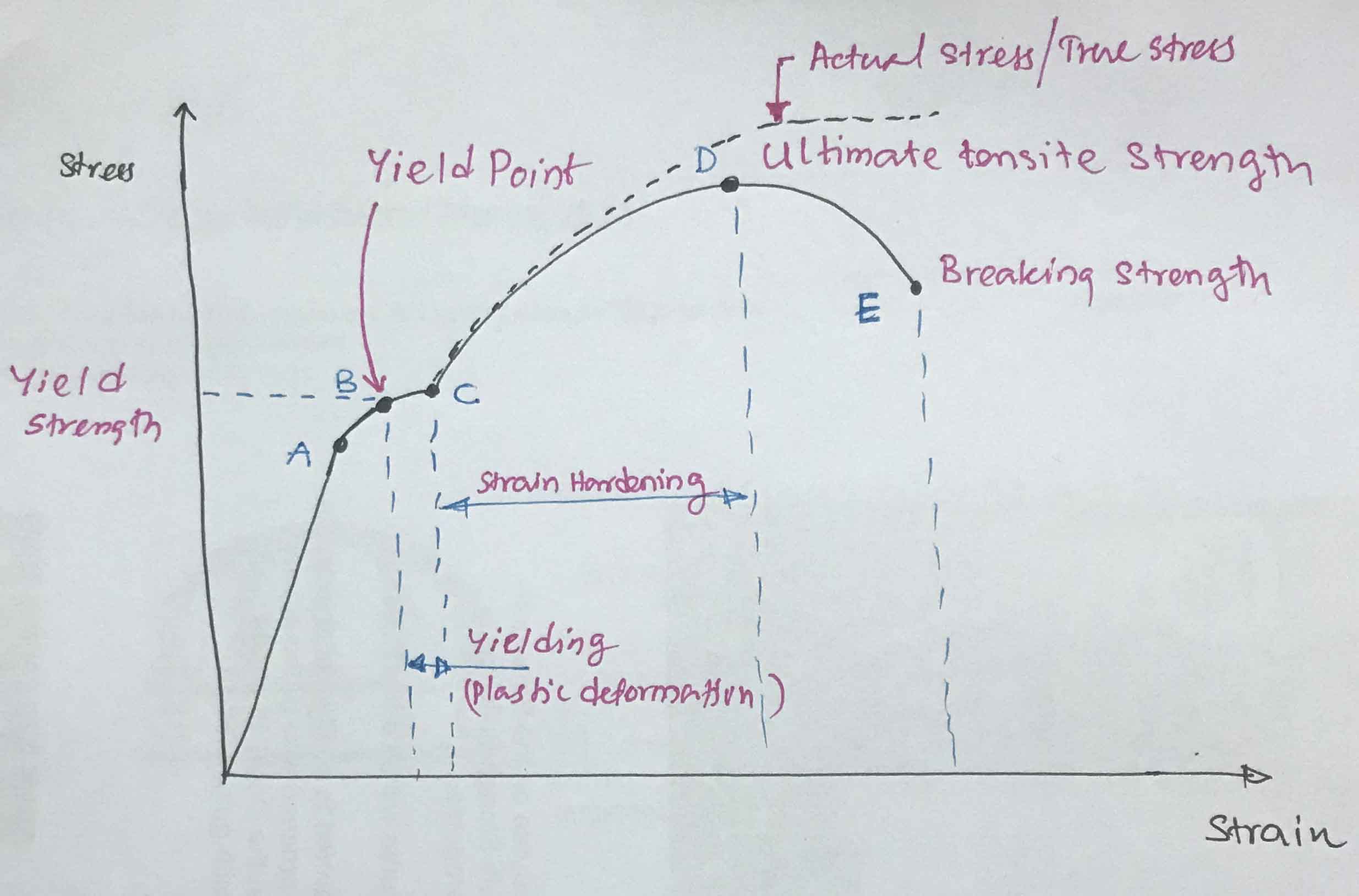

Now let see the typical stress-strain relationship of the reinforcement bar to understand the development of the tensile strength.

- When the load is applied to the rebar, its strain gradually increases. Up to point A, stress and strain are proportionate and reduction and increase in the load within this range do not subject to any permanent deformation of the bar.

- The proportion of stress and strain in this range is also known as your modules or modulus of elasticity. (E = σ / ε ).

- Increases in the load, stress reaches point B called the yield point where the yielding of reinforcement is starting. The stress at which yielding starts is called the yield strength.

- Point B to Point C is the yielding of reinforcement which is an increase of strain at a smaller change in strain and this a plastic deformation (permanent) in the bar.

- Beyond the yield point, the material changes its crystal structure and becomes stronger resisting to deform. Therefore, additional stressing is required to produce the additional plastic deformation beyond Point C. This phenomenon is known as strain hardening. At the end of this process, load reaches the its maximum value.

- The maximum stress (Point D) is the ultimate tensile strength it reaches before reducing the stress.

- Stretching the bar beyond point D, the bar subjected to a reduction in cross-sectional area. This localized reduction in the crossectional area is known as necking.

- With the reduction in the cross-sectional area, the load-carrying capacity of the bar reduces significantly and ultimately it fails at Point E. The strength at which rebar fails is known as breaking strength.

- In addition, there is divination to the above curve as indicated in the dashed line with the reduction in the crossectional area. Thus, the actual stress/ true stress will higher than that indicated.

This is the process connected with reinforcement testing. As discussed above, the maximum stress the bar can bear is known as the ultimate tensile strength.

Design Code Requirements

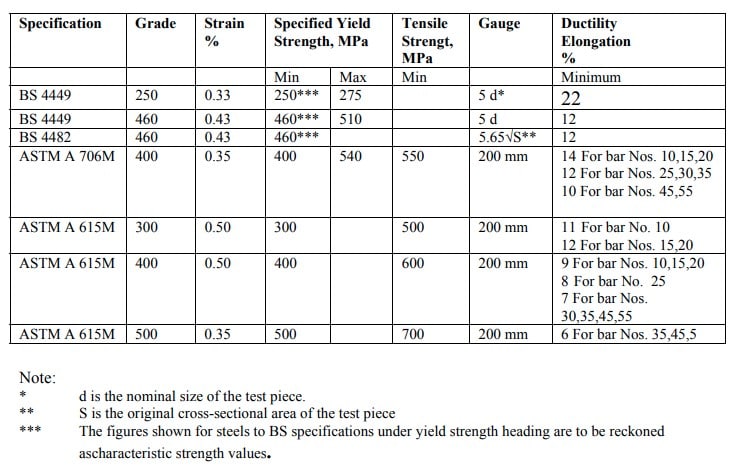

According to BS 4449: 2005, there is no limiting value for the Tensile strength of the reinforcement bars. However, the standards like ASTM have specified a minimum value based on the grade of the steel.

The following table extracted from a technical document indicated those values.

The article reinforcement test could be referred to for more information on reinforcement testing.