Low Heat Cement

Low heat cement also can be identified as the type of cement that generates low heat of hydration during its initial chemical reaction.

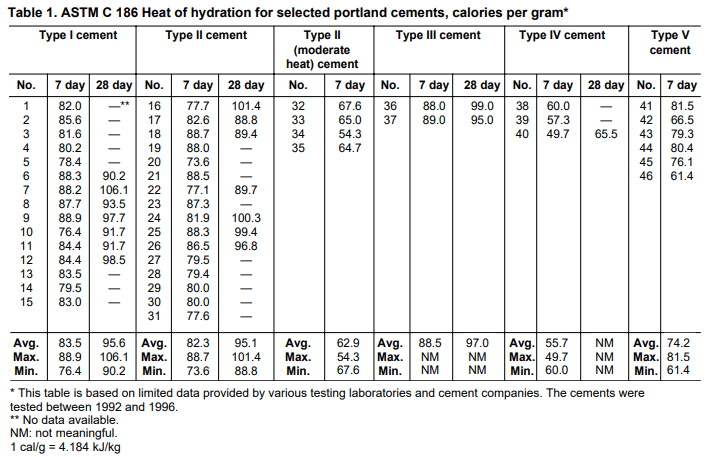

According to the classification of cement by ASTM C150, these types of cement are classified under Type IV – Low Heat Hydration.

Further, low heat cement also classified based on its performance by ASTM C1157 as Type LH – Low heat of hydration.

Out of the four main components in the concrete, C3S and C3A are the main contributors to the heat generated in the hydration process.

The amount of C3S and C3A are reduced in low heat cement and then the hydration process will be slow. As a result, the rise of the temperature will be limited.

As indicated in the above table of ASTM C186, the average heat generated by the Type IV cement is low when compared with other types of portland cement.

Why we need low Heat Cement?

The rise of the heat of hydration in the concrete leads to cracking of concrete. We need to limit the temperature rise to avoid the craking.

Further, even when reinforcement is provided, concrete gets cracked due to the rise of the heat in the concrete extensively.

There are several alternatives to this.

- Use low heat cement

- Add fly ash

- Reduce the temperature of the concrete at the time of pouring by various methods.

- Colling of concrete during the hydration process.

The article methods of limiting temperature of concrete could be referred for more information on other methods (2-4 methods above list) to limit the rise of the heat in the concrete.

Out of the above methods, if available, the easiest method is the use of low heat cement.

It is widely used in large constructions such as dams. There will be a large volume of concrete pouring in these types of construction. This concrete is susceptible to cracking due to the rise of the heat generated in the hydration process.

Since the cracking of concrete is severe affects the serviceability and durability of the structures like dames, it is very important to avoid cracking. Further, in some of the structures, there are no reinforcements that are more critical in terms of cracking.

Therefore, the use of low heat cement to reduce the heat of hydration is a good option whenever possible.

Some Important Information

- Since the rise of the heat is less in the hydration process; the rise of core temperature, the temperature difference between the core and the surface and temperature gradient is reduced.

- Initial strength gain is slow but it gets strength with time and significant improvement in the strength is observed.

- Excellent resistance to the drying shrinkage.

- Excellent durability performance.

- High resistance to chemical attacks.

- These types of cement cannot be used in cold weather environments.

- The cost for the cement could be higher than other types of ordinary portland cement.