Types of Concrete [32 types]

Types of concrete used in the construction are categorized based on strength, nature of concrete, the material used, etc. are discussed in this article.

Different types of concrete made with different methods are also discussed in this article you to be aware of types of concrete in detail.

Let’s see what is the concrete.

Concrete is a combination of cement, sand, coarse aggregate and water. When the mix becomes hardened from the hydration process becomes the concrete.

Main Component of the Concrete

- Cement

- Water

- Sand/manufactured sand

- Coarse aggregate

- Admixtures

Properties of Concrete

The main properties of concrete could be listed below.

- Compressive Strength of Concrete

- Durability of concrete

- Resistance to Heat or Radiation

- Workability of concrete, etc.

Why do we use concrete?

Concrete is very strong when hardened and it has higher compressive strength. The chemical reaction of the cement and the water greater the strong bond.

We used aggregate to made concrete and the chemical reaction create a strong bond between the ingredients.

Concrete admixtures such as retarders, superplasticizers, high rage water reduces, etc. are added to the concrete to enhance the strength.

How to Make Concrete

There are two methods to make concrete.

- Hand mixing

- Machine Mixing

The most conventional method of making the concrete is the hand mixing of concrete. Based on the mix proportions, concrete mixing can be done.

The article concrete mixing could be read for further information on the concrete mixing method and their ratios.

Machine mixing is done by a batching plant or using the concrete mixture. In general, concrete mixing in the batching plant is done as per the mix design verified with trial mixtures. These types of concrete are classified as ready mix concrete.

Types of Concrete

let’s discuss the different types of concrete in detail.

Plain or Ordinary Concrete

Plain or ordinary concrete is the normal type of concrete that is not used as a structural element. They do not have reinforcement also.

Production of the plain ordinary concrete is done by volume batching mainly.

Plain concrete is not that strong and it can not bear tensile stresses greater than concrete tensile capacity. Further, plain concrete is weak in vibration loads.

Reinforced Concrete

The most widely used type of concrete is reinforced concrete. There are different classifications for reinforced concrete.

The concrete is strong in compression and weak in tension. The tensile strength of the concrete is about 10% of the compressive strength of the concrete. Therefore, reinforcement is provided to the concrete to enhance the compressive strength where required and reinforcement is provided where the tensile stresses are developed.

The use of the rebar in the concrete has made a significant impact on the strength development in the concrete in addition to the increase in strength of the concrete (increase in the concrete grade).

Prestress Concrete

One of the modern construction techniques developed in the construction industry is prestressed concrete technology. Though it is an old technology, its area of construction has developed considerably.

Usually, the prestress concrete is made of a higher grade of concrete as they are subjected to high compressive and tensile stresses during the prestressing and loading.

Since the tensile strength of the concrete is also considered for the design of prestressed structures, having a higher grade of concrete is an advantage.

Precast Concrete

As the name implies, precast concrete is the type of concrete that is cast early not like cast-in-situ concrete. Precast concrete is made as structural and nonstructural concrete elements.

Concrete kerbs, stands, etc. are made as nonstructural concrete. Floor slabs, drain covers, concrete beams, columns, etc are in buildings can be considered as key precast elements.

The use of precast concrete adds more advantages to the projects as it reduces the construction time. On some occasions, it reduces the cost of construction. In addition, there are many indirect advantages to the use of these types of concrete.

Roller Compacted Concrete

Roller compacted concrete type of concrete is used in major construction works. It is the type of mass concrete used to fill a larger volume of concrete. Nominal reinforcement may be used to avoid surface cracking etc.

The size of the aggregate such as 75mm is used to make the roller compact concrete in dams.

The factors such as durability of concrete, strength, workability, heat of hydration, aggregates, water content, etc are considered in the mix design.

The article on roller compacted concrete could be read for further information.

Light Weight Concrete

Lightweight concretes are types of concrete having low weight when compared to normal concrete.

The use of the low-weight aggregate reduces the density of the concrete. Generally, lightweight concrete has a density of less than 2000kg/m3.

Lightweight concrete is used in situations where the reduction of the weight is expected. In addition, it could be used for concrete filling where required the rise the concrete levels or required to protect the structures.

High-Density Concrete

The usual density of concrete is around 2400kg/m3. High-density concrete has a higher density in the range of 3000-4000kg/m3.

The higher density of the concrete is due to the use of the higher density aggregates.

These types of concrete are used in the construction of atomic power plants or similar types of structures.

Self Compacting Concrete

There are situations we can not do the compaction of concrete. Though there are methods like the vibration of concrete or any other, depending on the nature of the structure or type of construction, compaction may not be practical.

Underwater concrete, mass column concrete, concreting of pile foundation, etc. are done by self-compacting concrete.

There will not be compacting of concrete by mechanical means or any other, the concrete itself gets compacted. The properties of the concrete are modified in such a way that no vibration of concrete is required for the compaction.

The article on self-compacting concrete could be read for further information.

Ready Mix Concrete

The most commonly used types of concrete are the ready mix concrete. It is easy to use and readily available and has comparatively fewer issues compared to hand mixing concrete.

Ready-mix concrete is made in the batching plant as per the approved mix design by the engineer. There are factors affecting concrete mix design that need to consider when the mix design is done.

The article, read mix concrete could be read for further information.

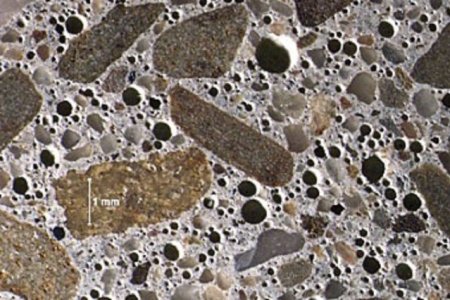

Air Entrained Concrete

The concrete that contained air bubbles is called air-entrained concrete. These are bubbles are not due to the lack of compaction of concrete. They are added for a purpose.

We can use air-entraining cement or admixtures to create the air-entrained concrete.

An increase in the workability of concrete, reducing the freezing and thawing effects, reduction in the bleeding and segregation, etc can be considered as some of the advantages of air-engrained concrete.

No Fine Concrete

The types of concrete that are made without using the fine aggregate are called the no fine concrete. There are different purposes of no fine concrete.

The main use of the no finance concrete is to use it as drainage. Since it is a concrete mix, it has the strength to bear the loads. Therefore, no fine concrete can be used where the high load is applied instead of typical drains.

The article on no fine concrete could be read for further information.

Vacuum Concrete

This type of concrete removes the water from the concrete by vacuum.

Vacuum concrete together with more water is poured and then the water will be vacuumed.

These types of concrete gain strength early which is about 10 days required to reach their compressive strength. The strength of the concrete is also greater than the nominal concrete by about 25%.

Shotcrete Concrete

Shotcrete can be identified as different types of concrete when compared to the other types of concrete.

Shotcrete is mortar or very thin concrete used for special surfaces. Normally, we need formwork to retain the concrete. With the use of shotcrete, we can avoid that up to a certain extent.

In soil nail construction, in slope stability, the ground surface is shotcrete by creating interconnection between the soil nail. In addition, shotcrete can be sued for repair works.

There are two types of short creates namely, dry mixed and wet mixed.

Fibre -Reinforced Concrete

The formation of the micro-cracks at the interface of mortar and the aggregate in the plain concrete is an issue. The use of fibre reinforcement reduces the formation of cracks of this nature and eliminates the weakness of the concrete.

The use of fibre helps to transfer the stress in the internal microcracks.

There are different types of concrete contending fibre.

- Discrete Fibre reinforced concrete

- Slurry Infiltrated Fibre Concretes

The following types of fibres are sued in the construction.

- Steel-fibre reinforces concrete – used for highway and airfield payments, hydraulic structures, fibre shotcrete, refractory concrete, precast applications, structural applications, etc.

- Polypropylene fibre-reinforced

- Glass-fibre reinforced concrete

Polymer-Impregnated Concrete

” In polymer-impregnated concrete, low viscosity liquid monomers or prepolymers are partially or completely impregnated into the pore systems of hardened cement composites and are then polymerized.

The partial or surface impregnation improves durability and chemical resistance.

Some of the applications of polymer impregnated concrete are surface impregnation of bridge decks, application in irrigation structures, structural members, marine and underwater applications, repair of the structure, etc.

Polymer Concrete

Polymer concrete is also known as resin concrete.

Polymer concrete is composite concrete where it replaces the cement water mix with the polymer in cement concrete. These are quite different types of concrete. Further, the manufacturing of polymer concrete is also made the same as cement concrete.

Polymer Modified Concrete

Polymer modified concrete is also called polymer cement concrete.

This composite concrete is obtained by incorporating a polymeric material into concrete during the mixing stage.

JET Cement Concrete

Jet cement concrete is also known as ultra-rapid hardening cement concrete.

These types of cement have many characteristics superior to ordinary portland cement. Short setting time, development of super high initial strength, etc. makes the cement more popular in the construction industry.

Jet cement is also called one hour cement as it is easily possible to obtain high early strength within an hour. The calcium fluoroaluminate is the material that causes the high early strength.

Some of the applications of jet cement concrete are building construction, concrete pavements, repair work, winter concrete, making concrete products, grouting, etc.

High-Performance Concrete

High-performance concrete is also known as performance-enhanced concrete. High-performance concrete is a special type of concrete that have special benefits that cannot be achieved from conventional types of concrete.

Some of the performance enhancements of the high-performance concrete are ease of placement and compaction without segregation, early age strength, long term mechanical properties, permeability, the heat of hydration, density, toughness, volume stability and durability.

Comparison of concrete grade as follows.

| Type of Concrete | 28-day Compressive Strength |

| Ordinary Concrete | 10 – 20 N/mm2 |

| Standard/Normal Concrete | 25 – 55 N/mm2 |

| High-Performance Concrete | 60 – 100 N/mm2 |

| Very High-Performance Concrete | 100 – 150 N/mm2 |

| Exceptional Concrete | > 150 N/mm2 |

Stamped Concrete

Stamped concrete is the same as ordinary concrete. It is a kind of architectural concrete that are used to gain architectural features.

Stamping is done when the concrete is in plastic condition. Based on the architectural requirements production of the concrete is done.

Pump Concrete

Any type of concrete can be categorized under the pump concrete.

When the structure is taller or when it is required to do the concrete early as possible, pumping of the concrete are done. Different types of concrete available can be used for pumping

The slump of the pumping concrete is maintained at a reasonable level to enable smooth pumping. Generally, the slump of the pump concrete is greater than 150mm.

Decorative Concrete

As the name implies, decorative concrete is the type of concrete that is used for decorative purposes.

These types of concrete are used in areas where the aesthetic appearance is important. Decorative concrete could be made from ordinary concrete.

Additions of colouring, moulding, etc make the decorative concrete.

Volumetric Concrete

Volumetric concrete is ordinary concrete. It is the type of concrete that is made by volume batching. The mix proportions are based on the volume of materials not by the mass.

Hand mixing or in small scale constructions, volume batching or mixing are done.

The article concrete mixing could be referred to as volumetric ratios for different grades of concretes.

Fly ash Concrete

There are modern researches to replace the concrete with fly ash significantly. Presently, as per the BS EN 197, the maximum percentage of fly ash to be used is 35%.

Fly ash is added to the concrete to improve the durability of concrete, reduce the heat of hydration of concrete, improve the chemical resistance, etc.

Further reading on the fly ash concrete could be made from the article fly ash concrete why should it be used.

Silica fume Concrete

Silica fume is a very fine material that is being used as a filler in the concrete. Due to its fineness, there are more enhancements in the concrete.

Same as the fly ash, silica fume also can be added up to 35%.

Further information on the silica fume concrete the article silica fume concrete – why it is in concrete

Ferro Cement Concrete

Ferro cement concrete is a type of reinforced mortar. It is a combination of reinforcement and mortar. It is also used for plastering work.

It is one old type of construction method initiated in the 1840s.

Ferrocement is used to construct relative thinner elements that required higher strengths. In addition, it is used to develop different shapes such as hulls for boarts, shell roofs and water tanks.

High Strength Concrete

High strength concrete is the type of concrete that have higher strengths. Mostly the concrete grade (cube strength) 25 and 30 are used in the construction.

As the durability requirements and load-carrying capacity improvement, the grade of the concrete is increased.

Generally, the concrete grade greater than 40 (40 N/mm2) is considered as high strength concrete.

Glass Concrete

Glass concrete is a type of composite concrete or reinforced concrete. The glass concrete is also called glass-reinforced concrete.

These types of concrete can be made from two methods.

- Using recycled glass

- Using fibre reinforced glass

Recycled glass is added to the concrete and used as normal concrete.

The glass fibre concrete also called glass fibre reinforced concrete is a very effective type of concrete.

Asphalt Concrete

Asphalt concrete is also known as asphalt.

It is a combination of aggregates and asphalt. It is not a type of concrete that is made of cement, aggregate and water.

Asphalte concrete is used in the construction work related to roads and it is a new invention of the construction sector.

Lime Concrete

Lime concrete type of concrete that is made of lime by replacing the cement. In the old days before the invention of cement, lime was used as binding material.

In some countries, limes are readily available. Those lime are used for construction.

Lime concrete is used for the construction of domes, floors, etc.

Rapid Set Concrete

These are special types of concrete that are made for special purposes. When is required the concrete to reach it strength quickly, these types of concrete are being used?

The use of quick setting cement or additive that accelerate the hydration process is the main method to produce the rapid set cement.

Rapid set concrete is very important in special construction works such as the replacement of bearing pads of the existing bridge where it required the strength of concrete early.

Smart Concrete

It is a type of concrete that is used to monitor the health of reinforced concrete structures.

This is done by adding a small quantity of short carbon fibres to the conventional concrete. It modifies the electrical resistance of concrete in response to strain or stress.

There is more research on these types of concrete and these types of concrete would be more popular in the future.