Mass Concrete – design and construction aspects

Mass concrete is the most ancient type of concrete used to build structures in history. As we can see today, old structures are larger in scale due to using only low-grade concrete to support the structure.

Defintion of mass Concrete – as per ACI

Mass concrete is any volume of concrete in which a combination of dimensions of the member being cast, the boundary conditions can be lead to undesirable thermal stresses, cracking, deleterious chemical reactions, or reduction in the long term strength as a result of elevated concrete temperature due to heat from hydration.

Mass concrete is a very useful type of concrete in larger-scale projects such as hydraulic structures. Let’s discuss the concrete in detail.

Properties of Mass Concrete

It is vital to be aware of the behavior of the concrete before using it for different applications. Mix design shall be done based on its properties and intent behavior during the service period.

- Strength of Mass Concrete

In general, these types of concrete are used in structural elements that do not require higher compressive strength. On other hand, when the structures build with mass concrete, it is not required to have a higher range of strength as there is a large area of concrete to carry the applied stresses.

It shall be made sure by the designer not to develop any tension stresses due to the applied loads on the strictures. However, there is a certain level of tensile stress that could be allowed to develop as concrete can carry tensile stress which could be around 10% of its compressive strength.

- Mass Concrete Mix Design

The most important component of these types of concrete is the mix design as there are many factors to be incorporated and need to be considered.

Some of the key factors considered in the mix design are as follows.

- Low strength requirements

- Use of low cement content

- Development of compressive strength by 56-90 days

- Use of additives such as Ground Granulated Blast Furnace Slag (GGBFS) and Fly ash to reduce cement content to reduce the heat of hydration.

- In addition, shrinkage effect and construction sequences, setting time requirements

Considering these factors concrete mix design is done. In addition, for other information the article, factors affecting concrete mix design could be read for more information.

- Thermal Effects

The main consideration of the larger volume concrete is the heat of hydration and cracking. The mix design shall be done in such a way that it reduces the hydration heat. Attention shall be made to the following factors to minimize the thermal effects.

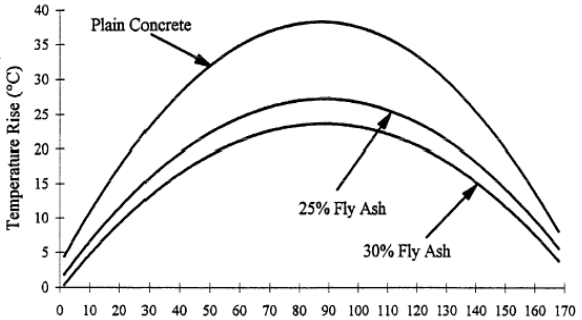

- As discussed above, using low cement content and use cement replacement such as fly ash [class F fly ash more suitable] and GGBFS could minimize the temperature rise.

- The rise of the core temperature shall be limited below 70-750 C.

- The temperature difference between the core and the surface shall be limited to 20-250 C.

- Carrying out a mockup test to measure the above limitation is achieved. If not, make necessary modifications to the mix design. This can be done by the continuous mass concrete temperature monitoring process.

- Cooling aggregates, adding chilled water, concreting at night time, etc. are some of the key aspects to be considered to reduce the rise in the temperature.

- Permeability Of Concrete

The permeability of the concrete depends on the porosity of concrete. Porosity can be controlled by the following factors.

- Adjust water-cement ratio while being in line with the mix design requirements.

- Carrying out adequate compaction of concrete

- Adequate curing

- Properties of cement – select suitable cement type

- Use of admixtures

- Types of aggregate used

- Durability

The durability of the concrete or the structure is the most important aspect considered in modern design and construction. Earlier, the main concern was the strength of the concrete. However, with the results of the old designed structures, no trend has been changed to durability-based designs.

Therefore, selection of the concrete grade, water-cement ratio, minimum cement content, and cement type shall be made following the durability requirements.

Use of Mass Concrete

Mass concrete is used mostly in large volume construction. In addition, there are other occasions where the mass concrete is poured without the reinforcements. Let’s discuss some of the applications in detail.

- Dam Construction

Mass concrete can be observed in dam construction. Dams like Hoover having the with of 200m have been constructed with mass concrete. It is great evidence that we can use large volume concrete for construction without reinforcement while maintaining the stability of the structure for very large lateral loads.

The article types of dam and force action on dam could be read for further information about dams.

- Retaining Walls

There are different types of retaining walls. Namely, there are reinforced concrete retaining walls, semi-gravity retaining walls, and gravity walls. The gravity retaining walls are built from mass concrete.

When there is a retaining wall, their will the lateral force is applied to the structure leading to develop tensile stresses in the face where the loads are applied. The gravity retaining walls are designed in such a way that there will not be tension in the concrete face or the developed tensile stress is less than the tensile capacity of the concrete.

The article on retaining wall failures could be studied for further information.

- Road Concreting

Roads are concreted with mass concrete without reinforcement in most instances. The contraction and expansion joints are provided at a regular spacing to meet the thermal contractions and expansions.

Design of Mass Concrete Structures

Not like reinforced concrete structures, the design of the mass concrete structure are not that complicated. However, there are many factors that the designer needs to look into when considering the constructability of the design.

The designer shall be fully aware of the material behavior when designing a structure of this nature. Otherwise, it will be ended up with a highly cracked, water leaking, and less durable structure.

The following factors to be considered in the design

- Selection of the concrete. The article on how to select concrete grades could be referred to for further information.

- Predict the rise in the core temperature and the difference in the temperature and take necessary action to control them avoiding cracking of concrete.

- Concrete mix design shall address the durability of concrete and strength requirements

- Flowability of the concrete for better performance during the construction.

- Assess the structural requirements for seismic effects. Since the unreinforced structures are weak with cyclic loading, necessary measures shall be taken during the design.

- Construction joints in the structure

- Watertightness of the structure

Main issues with mass concrete

- Flow problem

- Crack problem

- Requirement of a large volume of concrete to maintain the stability of the structure.

- Durability issue of the concrete

- Reduction in the strength