Cold Joint in Concrete | Why Important to Know

Cold joint in concrete a structure can be occurred due to the lack of attention of the supervision team or unawareness of the setting time of the concrete.

Cold joint forms in concrete due to several reasons that we discuss in this article.

What is a Cold Joint in Concrete? Why does a Concrete cold Joint form ?

A cold joint is a joint that is formed between two pours of concrete when the second concrete pour is placed after starting the setting of the first pour.

After the initial setting time of the concrete, concrete starts setting. When new concrete is poured after that there will be a separation in the layers.

Further, lack of penetration of the two layers thought adequality vibrated could occur.

Cold Joint Vs Construction Joint

| Cold Joint Concrete | Construction Joint |

| Form due to a construction error | Construction joints are created intentionally where required. |

| Inadequate bonding could be observed | Unless poor construction practices, but there are no such issues. |

| There could be strength issues | There will not be such issues. |

| Could be avoided with best construction practices | Place as required by construction. |

Key Facts about Cold Joints in Concrete

Let’s discuss the key factors to be aware of the cold joints in concrete.

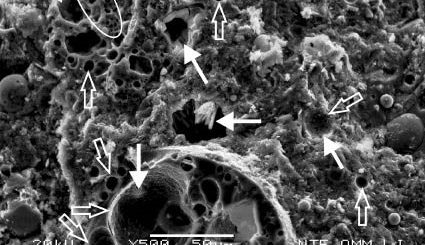

- Lack of Bonding

The formation of a concrete cold joint creates a weak bond between two concrete pours. It is due to the placement of concrete on concrete at has started hardening (setting).

The weakness of the joint depends on how late we pour the new concrete. Later we pour weaker the joint. If it is quite delayed, there could be separations in the joint.

- Reduce strength and Durability of Structures

Sine the new concrete is poured on the concrete that has started setting, there will be strength issues. Further, the tack of setting and improper bonding of the joint could create durability issues in the concrete.

Thus, cold joints in concrete exposed to the external environment could result in the durability of concrete.

- Water Leaks

There are possibilities of water leakages through the cold joints. If there is a cold joint in a raft foundation not having waterproofing, there could be water leakages.

Even for small slab on a floor constructed in a toilet area could lead to water leakages if there are cold joints.

- Deterioration of Concrete

Formation of the cold joint in concrete results in weak concrete. It could lead to early deterioration.

This may not significantly affect the internal areas having cold joints. When joint is exposed to the external environment, there are high possibilities of deterioration of concrete.

Poor compaction of the concrete at joints also could lead to this issue.

- Tensile Failures

Though the cold joints in concrete are not an issue structurally when compression stresses are applied, it is weak in tension.

If the cold joint is formed in an area where the tensile stresses are applied, it is required careful examination of the joint to avoid structural failures.

The formation of cracks, separations, etc., could be examined initially. Since the reinforcement will be provided for the section having tensile stresses, early warnings could be there before any failure.

- Aesthetic Appearance

Clear separation in the colour of two pours could be visible to the naked eye. This will be an issue in a location where the aesthetic appearance is a concern.

How to Prevent Cold Joints in Concrete

Cold joints can be avoided if the construction is planned properly. It shall be done with proper resource allocation and with the correct evaluation of strengths and weaknesses.

The following can be considered important to avoid cold joints in concrete.

- Concrete Pouring Sequence

Having an initial assessment of the available resource is very important when proceeding with any nature concreting work. The work may be a small slab or it may be a very large; thick concrete, the construction team should be aware of their strengths and weakness.

Accordingly, the poring sequence shall be placed. The size of a pour; high, width and length shall be decided based on the rate of concrete receiving to the site and the time taken to pour such concrete.

If your length is too long or if it takes more time to reach the initial point due to the selection of a large volume for singe pour, you may adjust it at the beginning of the concreting.

The logic is pouring concrete on old concrete before it starts hardening. That is pouring concrete before its initial setting time.

When it gets delayed to lay the new layer, we can pour the concrete on the old layer to make the joint new. This can be done especially when the concrete supply is slow.

- Setting Time of Concrete

In general, the setting time of the concrete is around one hour.

If we add the admixtures, we can extend this time. Generally, we could maintain the setting time of the concrete for around three hours. However, this will depend on the site conditions and it could be adjusted to meet the site requirements.

We use the admixtures, and retarders, to delay the initial setting time of the concrete.

How to Test Cold Joints in Concrete

It is required to assess the condition of the cold joint in concrete when the structure element is very important. It doesn’t mean that we don’t need t check the other concretes having a cold joint.

There are several methods to evaluate the condition of the cold joints.

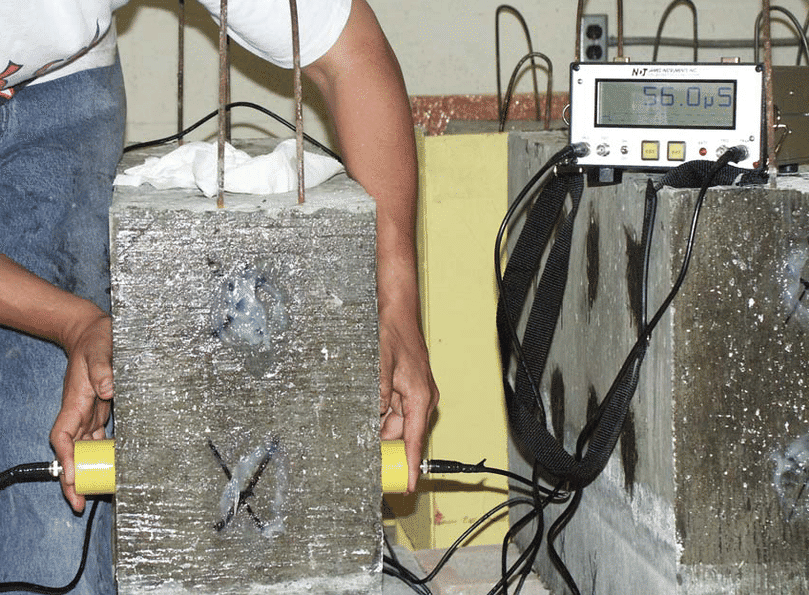

- Ultrasonic Pulse Velocity Test.

This is a non-destructive testing method that is used to determine the quality of the concrete.

Depending on the velocity of the waves sent through the defective concrete, we can determine the quality of the concrete.

- Impact Eco

This test is used the evaluate the concrete and masonry structures. This is a kind of non-destructing testing method used to determine the properties of the structure based on the waves generated due to the pulse.

- Rebound Hammer Test

The rebound hammer test is one of the most popular non-destructive testing methods used in the world to determine the Characteristic strength of concrete.

The strength of the concrete at the cold joints can be evaluated using this method

It is required to be aware of the principle behind this test. The rebound hammer test measures the property. It does not measure strength. Therefore, it is required to have another destructive test method such as core testing to develop a core relation to determine the strength of concrete from the rebound hammer test.

The article, asses in-situ compressive strength of structure could be referred for further information on the relationship between the non-destructive testing and destructive testing.

Concrete Cold Joint Repair

Best practice should be avoiding the cold joint in concrete. However, there are cold joints in concrete due to an unavoidable reason, it is required to take measures if it affects the structural stability.

Further, it should be noted that cold joint repair is challenging when compared to the other defective concrete repair methods. The following methods can be highlighted.

- Applying a bonding agent could be done to improve the bonding.

- Use of ground could be an option to improve the workability of the join. It would improve the possibility of vibrating two layers together.

- Adding dowel bars could be done to improve the strength of the joint.

- Check the possibilities of forming construction joints. Sometimes it will be the best option rather than having a weak joint. Especially, in areas where there will be tensile stresses applied. In addition, special attention shall be made to forming cold joints in the concrete wall as it could lead to durability issues.

- When there are cracks in the concrete cold joints, they could be repaired with conventional concrete crack repair methods such as epoxy grout injection methods or any other similar method.