Slab Types – deep review on types, design and construction

As shelter or to occupy different slab types are constructed. Slabs can be constructed from concrete. Apart from that floors can be constructed from steel or timber too.

In this article, we are discussing the concrete slab which could be constructed as reinforced concrete slabs, post-tension slabs, or pretension slabs.

Let’s discuss each slab type of slab in detail. The categorization of the slab types is based on the nature of the structure, material used, load transfer mechanism, etc.

Two Way Slab

One of the most common types of slabs is the two-way slab. The classification of these slabs is based on the load transfer mechanism.

In two-way slabs, loads applied on the slab are transferred in both directions. Four edges of the slab are rested on the concrete beams or maybe on the steel or any other supports such as concrete walls.

These slab types are more common in building construction. Generally, the thickness of the slab is in the range of 125 -200mm. On special occasions, these thicknesses could be increased as per the requirement of the structural design.

The desing of the slab will be based on the moment coefficients and shear force coefficient that are provided in the relevant standard based on the boundary condition of the slab. In addition, computer modeling could also be done to find the being and shear forces in the slabs.

One Way Slab

Loads will be transferred is on one direction. There will be minimal load transfer in the longer direction. The loads in the slab will be carried by the beams along the short edges.

One-way slabs are not economical when compared to the way slabs as they transfer the loads in one direction. We could be required to provide a higher area of reinforcement and slab thickness comparatively due to the one-way nature.

The design process is the same as the two-way slabs.

Flat Slab

As the name implies, the flat slab is comparatively different from other types of slabs. There are no beams to support the slab. The bottom of the slab is level most of the time except for some affections.

There are different types of flat slabs constructed based on the applied loads on the structure. Having a uniform thickness is always not adequate to carry the applied load. On these occasions, we modify the slab thickness or increase the slab thickness only where required.

- Flat Slab – Slab having a uniform thickness

- Flat Slab with Drop Panels – Slab thickness increases to carry the bending moment and shear to a certain extent

- Banded Flat Slab – Drop panels are connected like a beam. This is a kind of beam. Slab thickness increases along the column strip.

- Flat Slab with Column Heads – There is a considerable increase in the bending and shear forces at column heads. Therefore, we increase the section around the column.

The load transfer mechanism of a flat slab is also the same as the normal one-way or two-way slab types. While the middle strip act like the normal slab, the column strip act like the beam.

Waffle Slab

A waffle slab is a combination of beams to support the slab. Beams are placed at regular intervals and at closer spacing. The thickness of the slab is also smaller in these types of slabs.

Waffle slabs are mostly constructed in places where the aesthetic appearance is more important.

Higher spans can be constructed with waffle slabs. However, the cost of construction could be higher compared to other slab types due to the increase in the volume of concrete and area surface area for formwork.

Ribbed Slab

Rib slabs are also somewhat similar to waffle slabs. Generally, there are rib beams to support the slab.

Rib slab types are constructed only on special occasions as a bit difficult to do the construction with the nature of the structure. Formwork arrangements are much more difficult compared to the other types of slabs.

The rib beam may be rectangular or tapered in shape. It could be decided based on the aesthetic appearance. The width of the rib beam could be about 75mm – 150mm. However, depending on the aesthetic requirements and the structural requirements, the depth and width of the beam could be selected.

Post Tension Slabs

Post tension slabs are more popular slab types among the other types of slabs due to their productivity in construction. Desing and construction of the post-tension slabs are somewhat different from the other slabs.

Mainly there are two types of post-tension slabs.

- Placing on the conduits in the cast-in-situ slab and carrying out post-tensioning after the concrete gets hard.

- Cast concrete slab panels and then do the post-tensioning.

Some of the advantages of the Post tension slabs are as follows.

- Slab space can be increased significantly compared to the normal reinforced concrete slab.

- There is no such increase in the cost with the increase in the span of the slab.

- Fewer beams are more favourable for services as well as to maintain the floor to floor heights.

- The use of the precast slab panels reduces the construction time.

Some of the aspects considered in the design of post-tension slab types are as follows.

- Generally, the slab weight is balanced by the upward press applied by the post-tension cables are done in the design.

- An increase in the span requires a higher thickness of the slab-like the normal slabs.

- Though post-tensioning is done, we need to provide a certain amount of reinforcement for the slab to control cracking.

Pretension Slabs

Pretension slabs are used in bridge and slab construction. It is required to have beams placed at regular intervals to support the pre-tensioned slabs.

These slab types are more efficient construction element that reduces the construction time significantly.

Regular size slab panels are cast and they are placed on the beams placed at regular intervals. These beams could be reinforced concrete beams, precast beams, or post-tensioned beams.

Pre Cast Slab

Precast slab construction is similar to previously discussed pre-tension slabs.

In this method, we constructed reinforced concrete slab panels and placed them on the beam placed at a regular spacing.

Precast slab panels can not be spaned like post-tension slabs or precast slabs.

Cantilever Slab

The most common type of slab constructed in the buildings. There seems no building without a cantilever slab. Generally, the slab is extended beyond the beam or support without support on the opposite edge the slab is called the cantilever slab.

In these slab types, the load is transferred in one way and only to one support.

Providing reinforcement adequately is very important for the cantilever slabs. Attention shall be made to the following.

- Design reinforcement shall be provided in the direction of the cantilever and they shall be placed at the top net.

- Sometimes, bottom reinforcement nets are not provided for the cantilever slabs as there is no structural strengthening required.

- However, it is recommended to provide bottom reinforcement to improve the durability of the concrete. Especially in tropical climates, where the ambient temperature rises up to about 30 – 340C, there are possibilities of cracking the slab due to the thermal expansions and contractions.

- Therefore, therefore, adequate distribution reinforcements shall be provided to avoid thermal cracking. It is suggested to provide distribution reinforcement at a spacing of 200mm at least.

The article cantilever slab design could also be referred to for further information on designs.

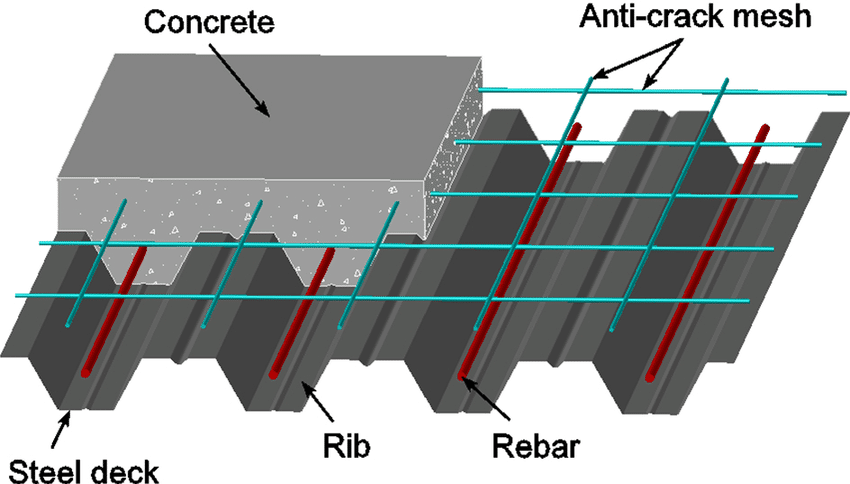

Composite Slab

Composite slabs are constructed mainly in steel buildings. When we required the concrete floor in a steel building, construction of the composite slab are done.

The composite slab is completely different from the slab types such as reinforcement slabs. Some of the special features are as follows.

- Composite action of the concrete and steel will carry the loads

- A Steel decking sheet is normally used as the formwork of the concrete slab too. Where required by the design, sports are used during the concreting.

- Composite slabs are spanned on singer direction like one-way slabs.

- The decking sheet acts as the bottom reinforcement. Bottom reinforcement is provided where required by the design.

- General, bottom reinforcement is provided to improve the fire resistance.

- Hogging reinforcement and crack controlling reinforcing are provided.

- Shear studs are provided to get the composite action of the beams

Slab On Grade

Instead of suspended slabs, we construct the slabs on the ground to support the ground floor. Though suspended slabs are heavily reinforced to carry the loads, slabs on grade are not as such.

Nominal reinforcement or BRC meshes are provided generally. On special occasions, we provide the reinforcement as required by the design. The construction of slab foundations is a good example of that.

In the event, we support the heavy load structure a thicker concrete will reinforce like a normal slab is provided.

Sunshades

Sunshades are sometimes called canopy slabs. They are constructed about the doors and windows to cut off the sunlight and to avoid the rainwater coming through the windows.

Sunshades are less reinforced concrete elements. Providing reinforcement to the sun shades is safer and it improves the durability of the concrete.

Kitchen Slabs

Kitchen slabs sometimes are called worktops. They are constructed not only in the kitchen, bathrooms, pantries, and many more locations.

The thickness of the slab is in the range of 50-100mm. depending on the supporting and space requirements.

BRC mesh or single reinforcement net are provided most of the time.

Cable Suspension Slab

These are the slab that are supported the suspension cables. They are in the suspension bridges.

The slab is supported by a steel structure hung by high tensile strength cables. These bridges are not common and are constructed on special occasions where we can have more support than other bridges.

Suspension bridge mostly construed across reivers.

Pitched Roof Slabs

The use of reinforced concrete slab types to cover the building is not common and new to the construction. There are old and new structures.

However, the construction of pitched roof slabs is challenging due to the nature of the structure. Pouring concrete in the sloping direction and working there is a bit difficult. Further, tieing reinforcement is also challenging.

It is the common practice to use low slump concrete for concrete pouring. In addition, higher attention shall be made to the thermal cracking of the concrete.

Providing adequate reinforcement to resist the craking in the immature concrete and during the service is a must to avoid water leakage through the roof if it is not further covered with roofing sheets. In addition, attention shall be made to the curing of the concrete.

Dome Slabs

Dome slabs are very special slab types where the design and construction are very challenging.

They are mostly constructed in structures where the aesthetic appearance of the dome is important and in religious places.

The nature of the structure creates difficulty in the construction. The curved shape makes it difficult for the execution process. Compute aid software is used to design the dome structures most of the time.

Bubble Deck Slab

Pouring a higher volume of concrete incurs a very high cost. Further, the most effective area of the concrete is close to the extreme fibres of the section.

This means the concrete in the middle part of the section is not contributing much to resist bending moments. It is required to resist the shear forces and to maintain the connectivity of the top and bottom parts.

A cavity is created inside the slab and the design is done according. The Constructin of bubble deck slabs is a bit challenging due to the difficulty of creating voids within the concrete. However, there are methods to do that.

Hollow Core Slab

Hollow-core slabs are also similar slab types to bubble deck slabs.

Instead of the bubbles, there will be a continuous hole in the slab section. These types of slabs are constructed in the bridge deck construction.

Removable flexible material or lost formwork will be used for the construction.

Hardy Slab

Hardy slab construction is done as precast construction or as cast-in-situ construction.

In simple terms, hardy slab construction is the construction of slabs using prefabricated blocks resting on the beams constructed at regular intervals. It can be described as follows.

- Blocks are constructed initially. The length of the block is in the range of 450mm. This could vary as per the design.

- These blocks are generally hollow blocks.

- One method is to place the precast or post-tensioned beams and rest the blocks on them and place a concrete layer with BRC mesh.

- Another option is to construct the cast-in-situ beams and place the blocks and lay filling concrete with BRC mesh.

- This is very fast and sometimes understood as cost-effective construction.

Sunken Slab

As the name implies, it is the type of slab constructed by lowering the slab’s top-level when compared to the other slabs. Apart from that constructing a different slab below the original slab to hide the service lines are also considered a sunken slab.

Sunken slabs are constructed in toilets areas, balconies, courtyards, etc.

The reinforcement detailing of the slab shall be done accordingly.