Types of Steel Beams

Different types of steel beams used to carry the loads from the structure to the adjoining support are discussed in this article.

Different classifications can be made to identify the types of steel beams. In this article, we are classifying the beams based on their geometry and the manufacturing process.

The following types of steel beams are discussed herein.

- I beam, H beam, W and S section

- Plate Girders

- Gantry Girder / Beam

- Rectangular Hollow Section and Circular Hollow Section

- Composite Beam

- Other Types of beams

Let’s discussed each type of beams in Detail.

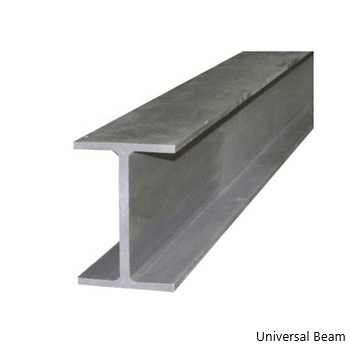

I Beam or Universal Beam

I beam is also known as the universal beam is a hot rolled section.

Universal beams can be identified as the widely used steel section in the construction. In most of the structures, we can observe these steel columns connected tot he universal beams to carry the loads.

Universal beams have higher stiffness in the vertical direction to carry the loads. The height of the section is greater than the width of the section.

I beam is also identified as an H beam when both the height and the width of the section are equal. That is the height of the section is equals to the flange width.

Further, they are identified as W and S sections too.

The main issue in the steel construction is the fire resistance. When the structural steel is exposed to the fire, its temperature increases rapidly, and also steel section subjected to the rapid deformation.

In addition, steel beams have less load carry capacity or stiffness when compared with the same height concrete beam.

Plate Girder

A plate girder is a steel beam that used mainly in bridge construction.

Those beams are customized types of steel beams. The customization is done based on the requirement of the project.

Plate girder bridges can be widely observed in railway lines.

Two flangers and the web is connected by welding to create the beam. The desing of the plate girder beams is not the same as the other types of beams.

Since the welding is done to connect the three plates together, the quality of the welding shall be checked regularly during the welding. A further test shall be done to make sure the welding is done correctly and it has adequate strength.

Gantry Girder

Gantry is a mechanical system used to transfer material or goods from one location to another.

Depending on the purpose of the use, these systems are categorized. In ports, we use gantry to lift containers, in the factory, we use gantry to transfer goods or material from one location to another.

A gantry is moving equipment that carries the load. Further movement of the weight along the beam also can be observed.

The design of gantry could be done conspiring the applied loads, moving load effects, etc. Generally, the desing of these types of steel beams is more difficult than the other types.

Medium to small scale gantries could be made from the hot-rolled sections. However, heavily loaded gantries could be made as plate girders.

Further, gantry beams are identified as special types of steel beams.

Rectangular Hollow Section and Circular Hollow Section

Mostly these elements are used in trusses, columns, and beams.

The rectangular hollow section and circular section are more efficient in terms of local failures. Universal beams are more susceptible to local bucking due to the nature section.

However, the rectangular hollow section is more resistant to the local buckling.

Further, rectangular hollow sections are available in different sections. However, in general, they are not produced like plate girders by connecting steel plates.

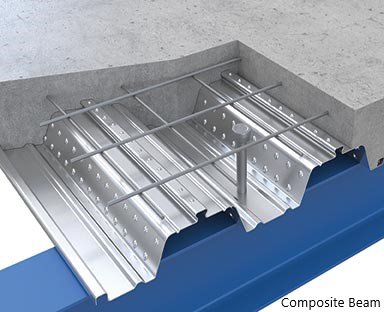

Composite Beams

Composite action is a combination of two or more materials. Composite beams are more efficient types of steel beams used in the construction of structures.

It could be a combination of a steel beam with the slab or constructing a steel beam together with a concrete beam.

A combination of steel beam and slab is obtained by shear studs. Shear studs welded to the steel beam are embedded in the concrete.

The composite action of the beam when we install the shear studs can be considered for the beam design. Due to the simplicity of desing, it is observed that some of the engineers do not consider the composite action when designing the steel beam. It is not an economical design.

Other Types of Beams

Angle sections such as “C” channels, “L” angles, etc. are also used as steel beams in the construction. However, these types of steel beams are not widely used as steel beams.

They are mostly used as elements in the trusses or part of a steel structure.