Plate Girder

A plate girder is a steel beam that is widely used in bridge construction. Depending on the design requirements and as per the nature of the structure; metal thicknesses for web, flanges, stiffness, etc are determined.

The use of the correct material (steel) having the specified strength and doing the welding are the two main factors to be attended to when developing the plate girder.

A plate girder is used when we need deeper sections having higher stiffness to carry heavy loads.

Further, there is a limitation in producing a hot-rolled section when the depth of the section is increased. Therefore, we have to use built-up sections that can carry large bending moments and shear forces.

Types of Plate Girders

There could be different classifications depending on the standards used or depending on the nature of the production of the girders.

There two types of plate girders.

- Reverted Plate Girder

- Welded Plate Girder

Reverted Plate Girder

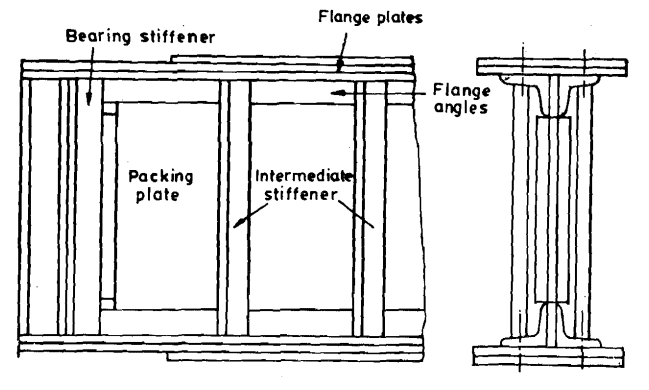

It is a combination of flanges, web, and other necessary stiffness. There are connected by a mechanical method, revert, and plates are not welded together.

- Generally, 90% of the shear is carried by the web.

- Connection of the web and the flange is stabilized by the angel sections reverted to the flange. Reverts need to be designed for the horizontal shear.

- The reverts that make the connection between the web and flange angles need to be designed for horizontal shear and vertical loads that applied to the flange when they transfer to the web.

- Angle sections are used as web stiffness in revert girders.

Welded Plate Girders

Welded plate girders are most widely used in construction due to the ease of production and it is a much more efficient type of girder.

These sections are mainly used in bridge construction. The plate girder bridge is very stiff and it can retain very high loads while resisting the lateral movements. This action can be observed in the railway bridges. Further, they are used to develop the box type girders.

There are empirical or approximation methods to determine the overall height of the plate girder and thickness of the flange and web.

Components of Plate Girders

Mainly there are five components in a girder. The assembly of that five-component is the complete girder. The basic requirement is to make an ” I ” girder having very high bending and shear stiffens in addition to the other local buckling resistances.

- Web Plate

- Flange

- Stiffeners (bearing, longitudinal, and intermediate)

- Splices for flange and web

- End Connection

Web Plate

The vertical plate of the girder is known as the web plate.

Its thickness is based on the design requirements and the height will also be decided based on the site condition and as per the loads applied on the web.

The web normally carries the applied loads on the flange as shear forces. The effect of the web is not usually considered when the design for the bending.

The web is susceptible to buckling when thinner and higher increase when the loads are applied. Therefore, different types of stiffness which will be discussing in this article, are welded to the web have its strength.

Flange

There is no specialty other than using a separate plate for the flange. The flange plate will be welded or connected by other means as discussed under different types of plate girders.

Not like rolled sections, we connect the web and the flange together to form the plate girder.

The flange is design to carry the bending action and stiffener or additional plate are provided as per the design requirements.

Stiffeners

Stiffeners are provided to enhance structural capacity avoiding the local buckling failures. In addition, they are used to carry the loads applied to the beam until it distributed into the beam.

The following types of stiffeners can be observed in these types of steel elements.

- Bearing stiffeners

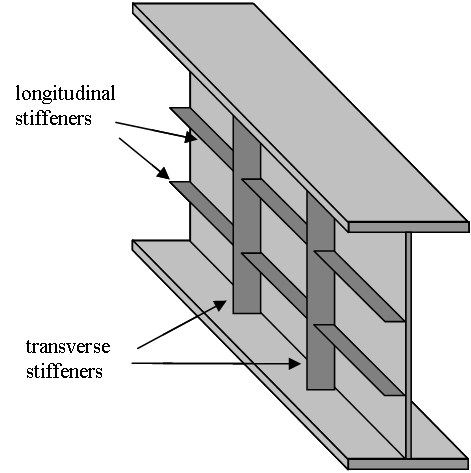

- Longitudinal stiffeners

- Intermediate stiffeners

The bearing stiffeners are provided at support to distribute the support reaction to the web without any buckling failures. There are jacking stiffness besides the bearing stiffeners for installations purposes as indicated in the following figure.

Steel plates welded in the longitudinal and the transverse directions are also used to strengthen the web.

The vertical or the transverse stiffeners can be commonly observed in most of the steel beams that carry heavy loads.

Splices for Flange and Web

It is the splice connection of the web and the flange of the girder.

When the length of the girder is less than the span, we have to have a splice connection.

This is a moment and shear transferring joint which provides beam continuation.

End Connection

End connection is the most difficult part of the structural detailing of a steel beam.

When there are continuation or if we are supporting the girder to some support, the connection needs to be designed accordingly.

However, most of the time, plate girders are kept as simply supported at the end support. In such situations, we have to provide the stiffeners at the end connection.

A similar design procedure is followed when designing the endplates and the stiffener provided vertically connecting the web and the flangers.

Application of Plate Girders

Plate girders are widely used as supporting structures in different areas. The following areas can be highlighted as key areas of use.

- Bridge construction

Plate girders are mainly used in railway and road bridges. Mostly the old railway bridges can be highlighted as plate girder bridges.

In addition, box girder bridges, beam bridges, military girder composite bridges, and half – through plate girder bridges are considered as it uses.

- Ships

- Gantry beams

- Oil and gas platforms

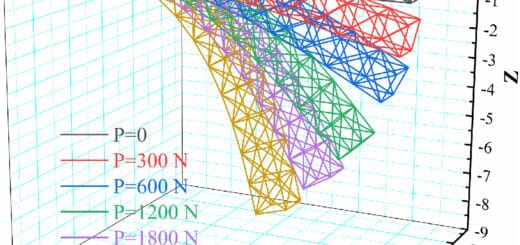

- Load testing

- Cranes

- Lifting structures

Advantages of Plate Girder

- They can be used to carry heavy loads

- Speed construction

- Grater stability

- High resistance to fatigue failures

- Easy to construct when compared with truss type bridges

- Easy for maintenance

Disadvantages of Plate Girder

- They cannot be used to support large spans

- Less architectural appearance

- A bit difficult to handle during the placement

- Production shall be done strictly in accordance with the design.

The articles were written on Steel Beam Design as per BS 5950 and Steel Beam Design Worked Example [Universal Beam] could be referred for more information on steel beam designs.

Further information on steel beams could be studied from the article Types of steel beams.