Single Angle Design for Tension as per EC3

Single angle design for tension in accordance with Eurocode 3 is discussed in this article. Desing of the angle section is more straightforward than a compression member design.

In this article, design procedure and worked example is included for ease of understanding the design concept and procedure.

Let’s discuss the design procedures

- Evaluate the material properties

Based on the plate thickness and the steel grade the yield strength (fy) and ultimate strength (fu) can be obtained from Table 3.1 of Eurocode 3.

Then, obtain the γm0 and γm2 from Clause 6.1. These values may change as per the national annexures.

- Calculate Desing Plastic Resistance – design tension resistance, NPl,Rd

Npl,Rd = Afy /γm0

- Calculate Nu,Rd

Nu,Rd can be calculated for angle section connected by bolts in one leg from Cl 3.10.3 (2) of EN 1993 – 1-8 as mention in Cl. 6.2.3 (5).

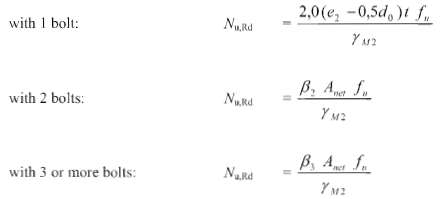

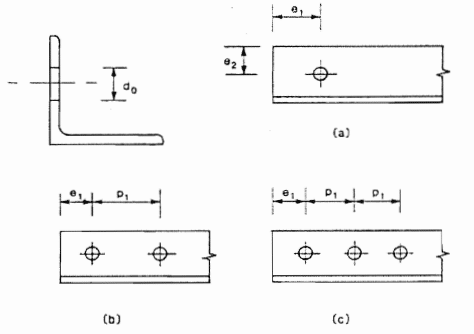

Depending on the number of bolts, there are three equations for capacity evaluation. For the angle section connected with a single bolt, the following equation can be used.

Nu,Rd = 2(e2 -0.5d0)tfu / γM2 – For Single bolt, select appropriate equation based on number of bolts.

When the number of bolts is more than one, the Anet needs to consider in the calculation.

When there is an equal angle section, Anet is the reduction bolt area from the gross section area. However, with unequal angles, the method is different.

- When the bolt connection is on the larger leg, Anet is the reduction bolt area from the gross section area.

- When the bolts connection is on the smaller leg, Anet is the reduction bolt area of the equivalent sectional area. For example, consider 100x75x10 section. When bolt connection on 75mm leg, section area shall be considered of angle section 75x75x10.

Similarly, other equations are given in the EN 1993-1-8 cl. 3.10.3 (2) could be used.

- Find Nt,Rd (Design Tensile Resistance )the minimum of Npl,Rd and Nu,Rd

- Check whether NEd / Nt,R ≤ 1.

Worked Example: Check angle section in Tension (Single Angle Design)

Desing Data : single angle design

- Agle section 60x60x6 mm

- Single bolt of diameter 12mm

- Steel grade S275

- Applied force 75 kN = NEd

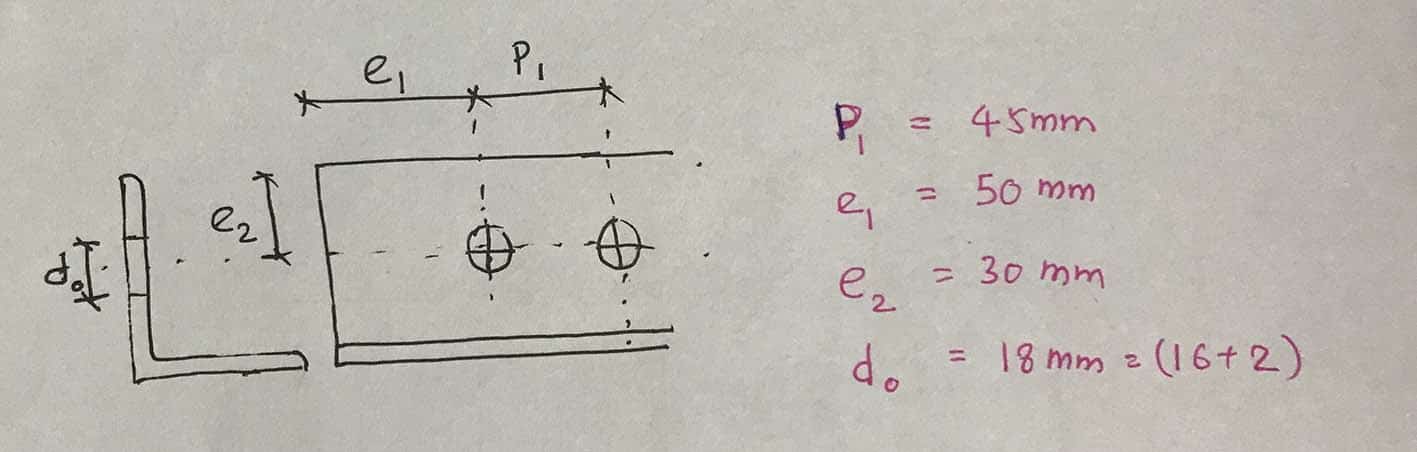

The following figure indicates the arrangement of the bolts considered for this worked example. The values are only considered for this single angle design.

Special attention shall be made to the design requirement for the bolt spacings. The minimum and maximum spacing of the bolts, end distance, edge distance, etc shall be in accordance with Cl. 3.5.

Desing Parameters

Steel grade S275

The thickness of angle section 6mm

From EN 1993-1-1 Table 3.1

fy = 275 N/mm2

fu =430 N/mm2

From clause 6.1, obtained the partial factors.

γm0 = 1.0

γm2 = 1.25

Cross sectional area of the plate; A = 695 mm2

Calculate Design Plastic Resistance of Gross Section, NPl,Rd

Npl,Rd = Afy /γm0 = 695 x 275 / 1.0 = 191.1 kN

The angle section is connected by one leg and there are two bolts in the section. Accordingly, as per the Cl. 3.10.3 of EN 1993-1-8, evaluate the section capacity.

Nu,Rd = β2Anet fu /γM2

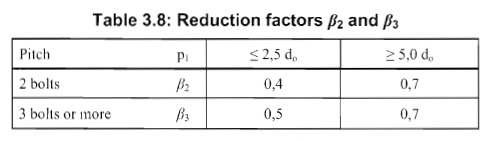

β2 = Reduction factor depends on the pitch P1 as given in Table 3.8 of EN 1993-1-8.

d0 = 16 + 2 = 18 mm

2.5d0 = 45mm

P1 = 45mm – refer above sketch

P1 = 2.5d0

From Table 3.8, β2 = 0.4

Since there is a single bolts across the cross section,

Anet = Section area – Hole area = 695 – 18 x 6 = 587 mm2

Nu,Rd= 0.4 x 587 x 430 / 1.25 = 80.8 kN

Design Tensile Resistance = Nt,Rd (Design Tensile Resistance )the minimum of Npl,Rd and Nu,Rd

Nt,Rd = Min (minimum of Npl,Rd and Nu,Rd ) = Min. ( 191.1 , 80.8 ) = 80.8 kN

Tension force, NEd

NEd = 75 kN

NEd / Nt,R 75 / 80.8 ≤ 1

Section is adequate

The article Steel beam design to BS 5950 also may be referred to enhance the knowledge in steel designs.